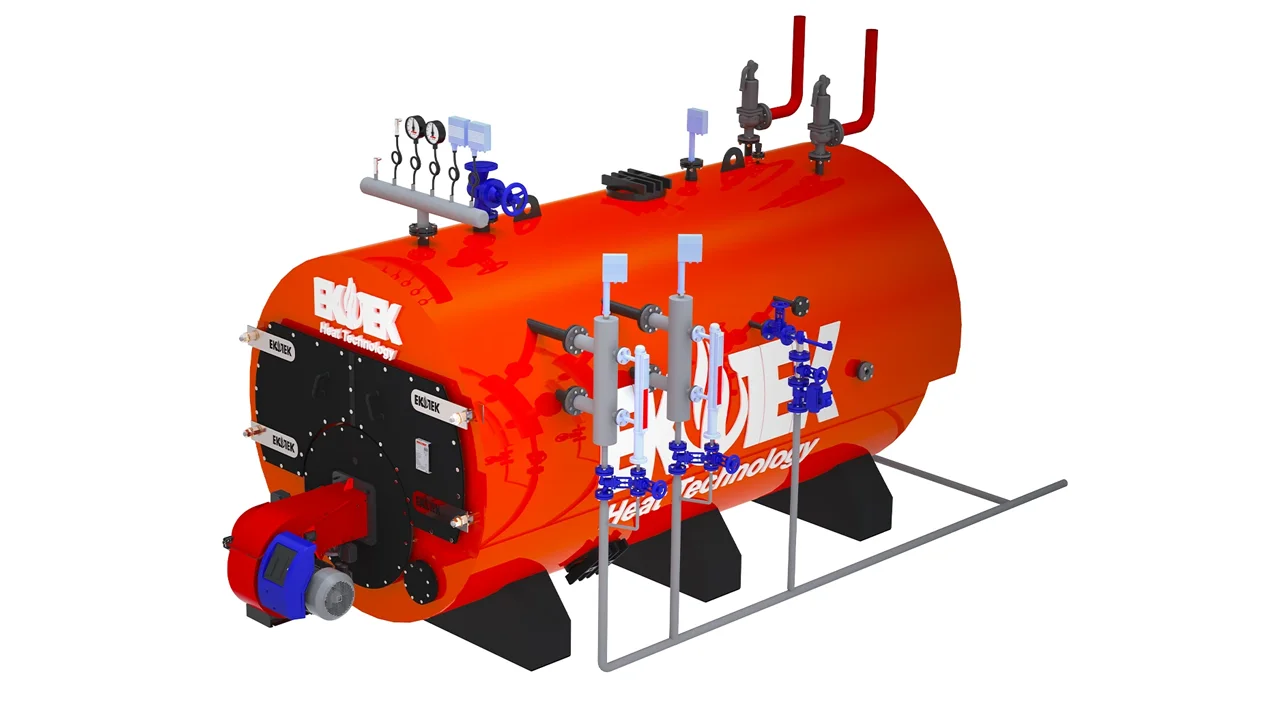

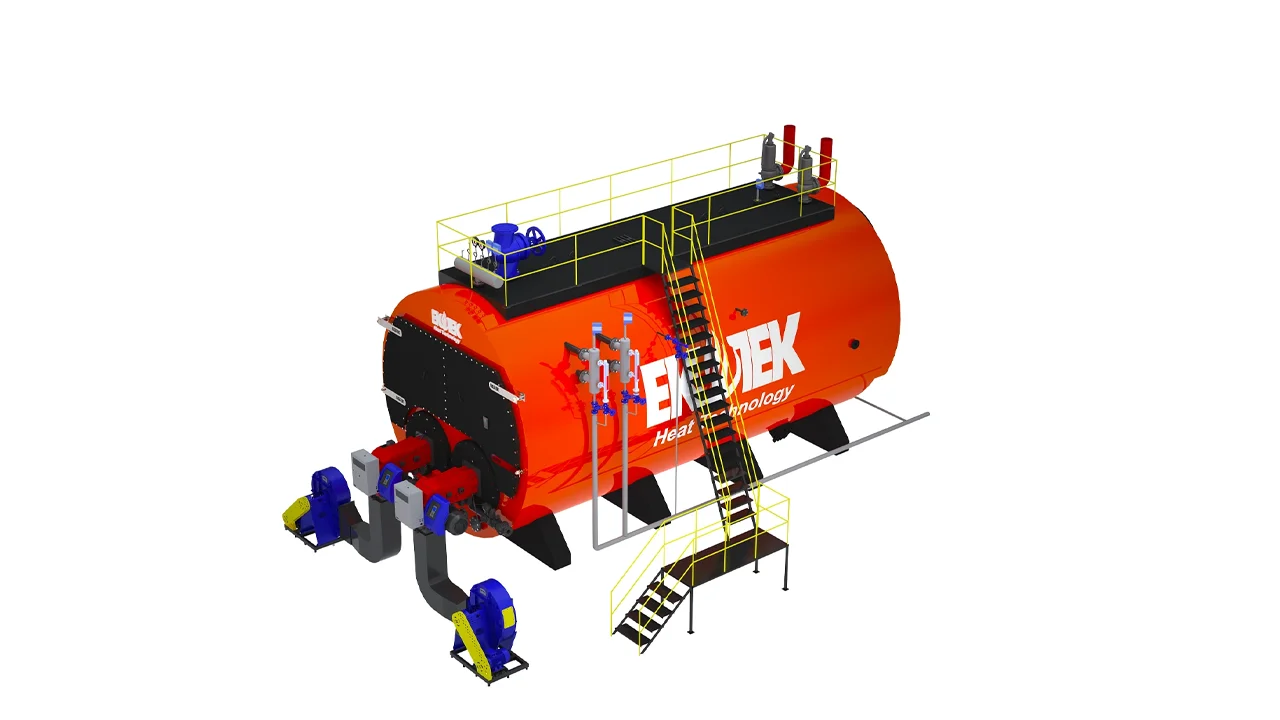

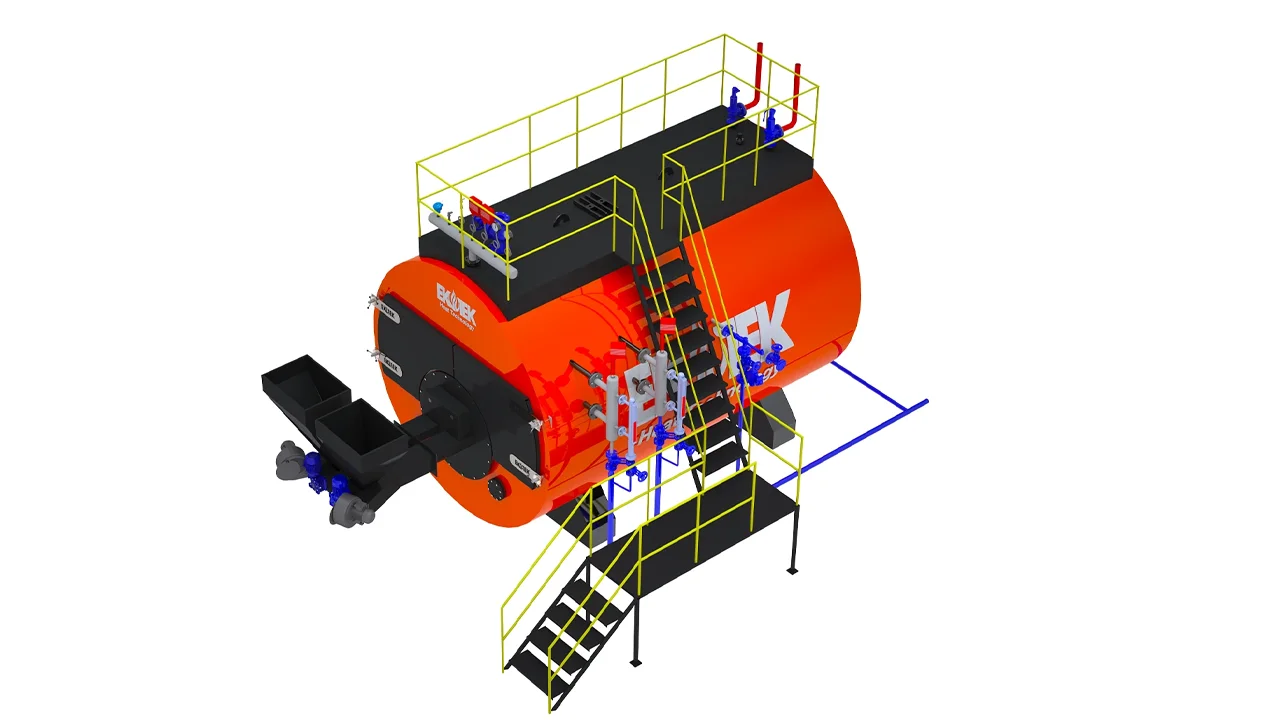

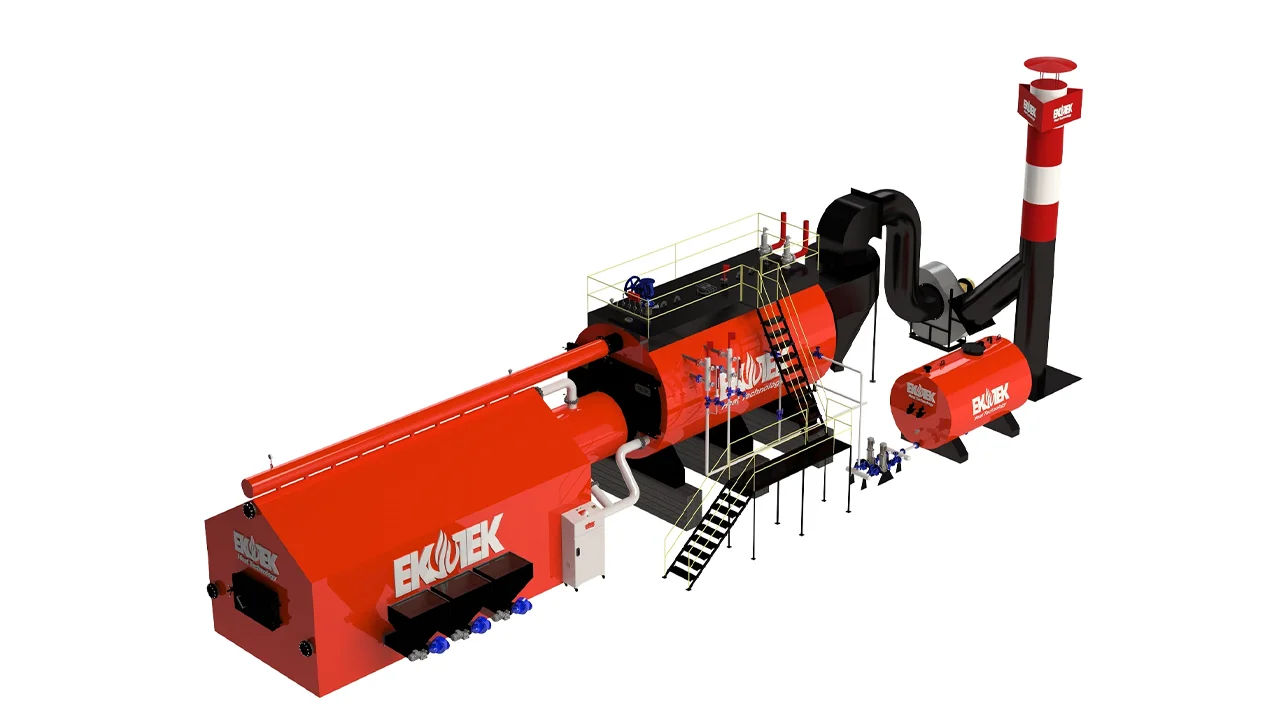

Industrial Boilers

Industrial boilers are systems that use different energy sources to convert water into steam, hot water, or thermal oil, providing heat energy for industrial processes. With applications ranging from factories to power plants, these boilers are designed to operate safely under high pressure and temperature. Equipped with modern technologies, industrial boilers not only generate energy but also deliver advantages such as high efficiency, low fuel consumption, and long service life.

-

Convert water into steam or hot water to supply energy.

-

Designed to withstand high pressure and temperature.

-

Provide a continuous energy source for industrial production.

Types of Industrial Boilers

Industrial boilers are categorized based on fuel type and design, offering tailored solutions for the diverse needs of different industries.

-

Steam boilers: Widely used in power generation, textile, food, and chemical industries.

-

Hot water boilers: Preferred in heating systems and central facilities.

-

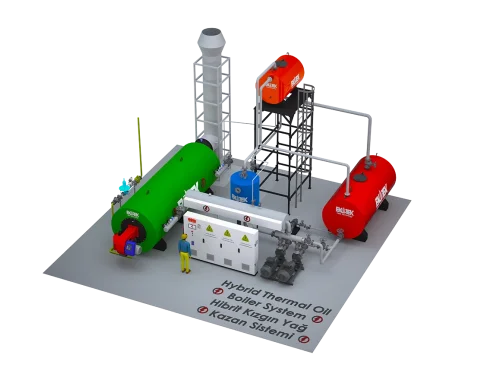

Thermal oil boilers: Safe solutions for processes requiring high temperatures.

-

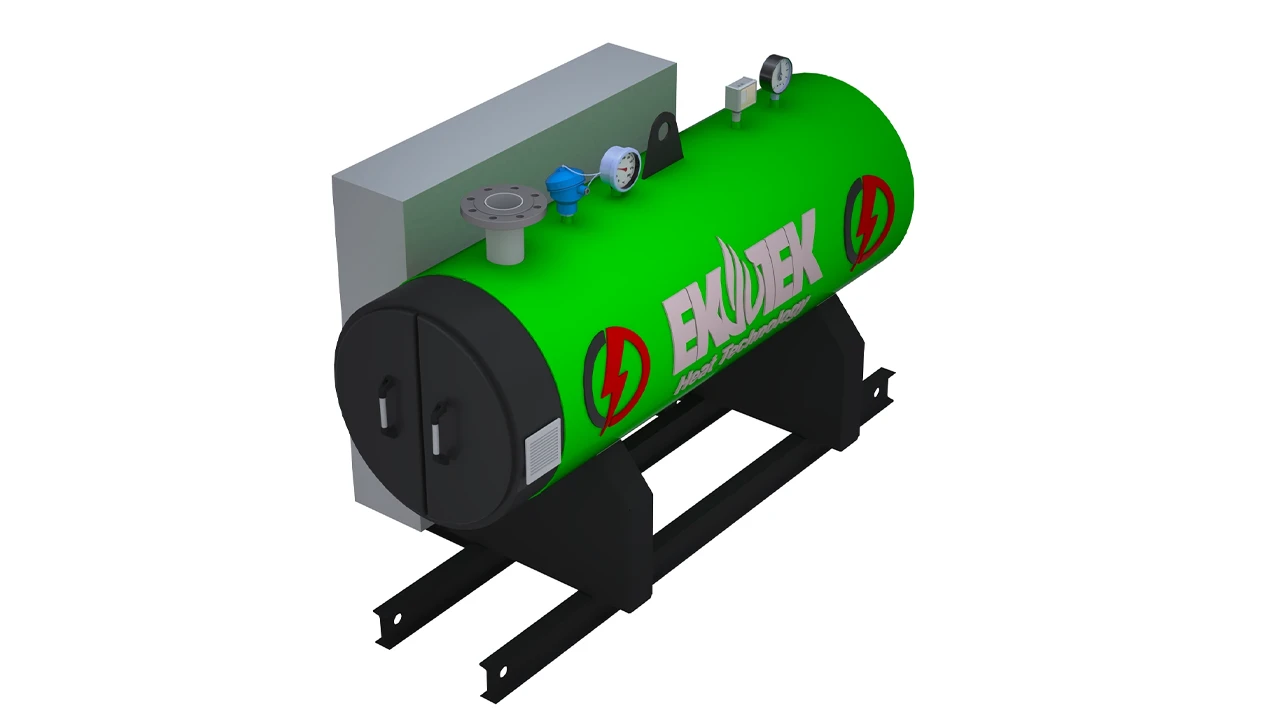

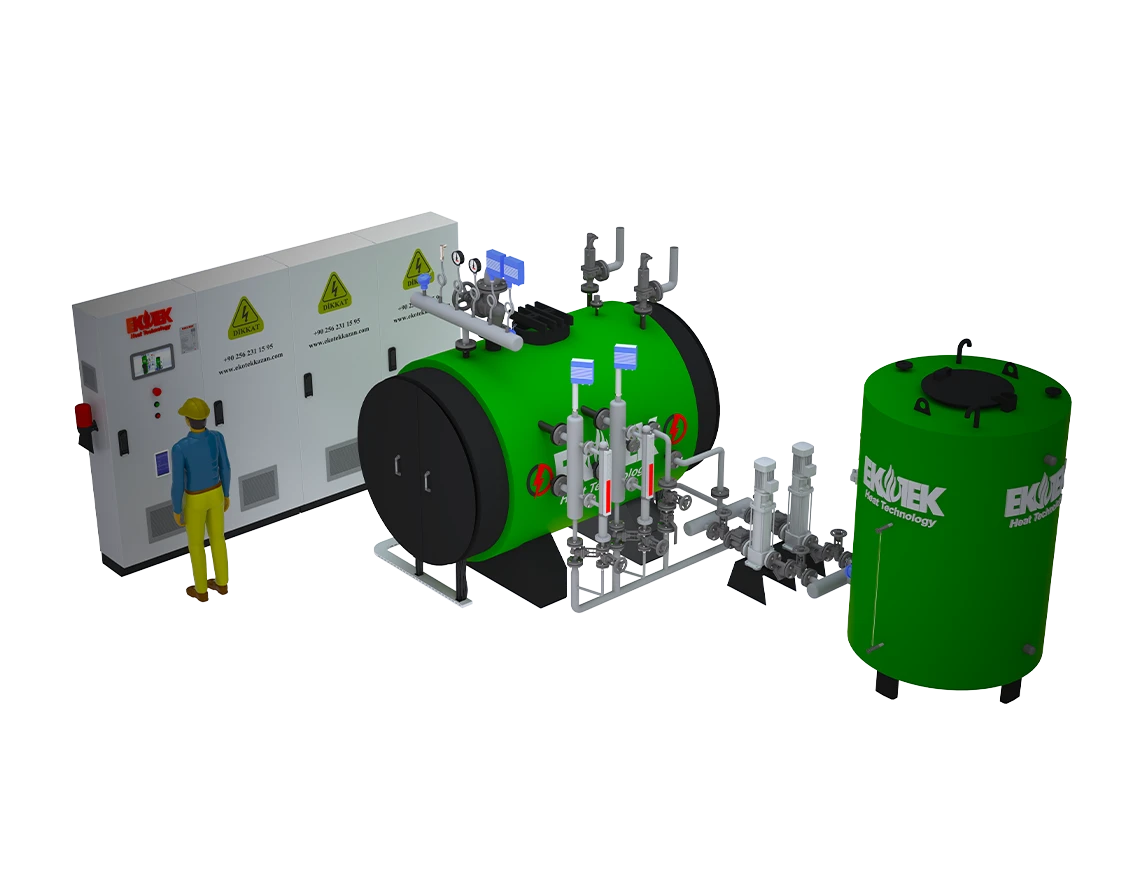

Electric boilers: Eco-friendly, emission-free, and compact solutions.

-

Solid, liquid, and gas-fired boilers: Flexible fuel options that bring cost advantages to businesses.