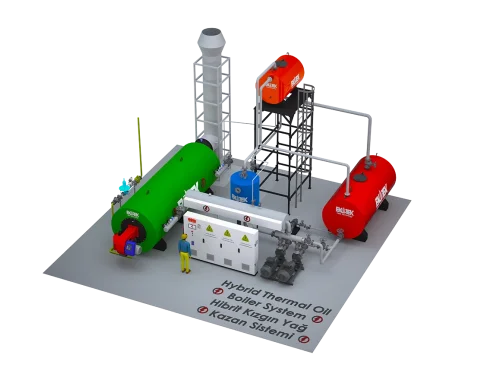

Hybrid Boilers

New generation hybrid boilers are high-efficiency boiler systems that operate with liquid and gas fuels such as natural gas, diesel, fuel oil, LPG, and LNG, while also being supported by electric energy. This structure offers flexible, sustainable, and safe operation to meet modern industrial needs.

Hybrid series ECO boilers operate with smart combustion technology until they reach the desired capacity in steam production. After the processes reach the required maximum level, it maintains the desired pressure and temperature with electrical energy in normal operation mode. In case of sudden pressure drop or sudden peak steam draw, it activates the main primary fuel system and provides the steam required by the system to the user.