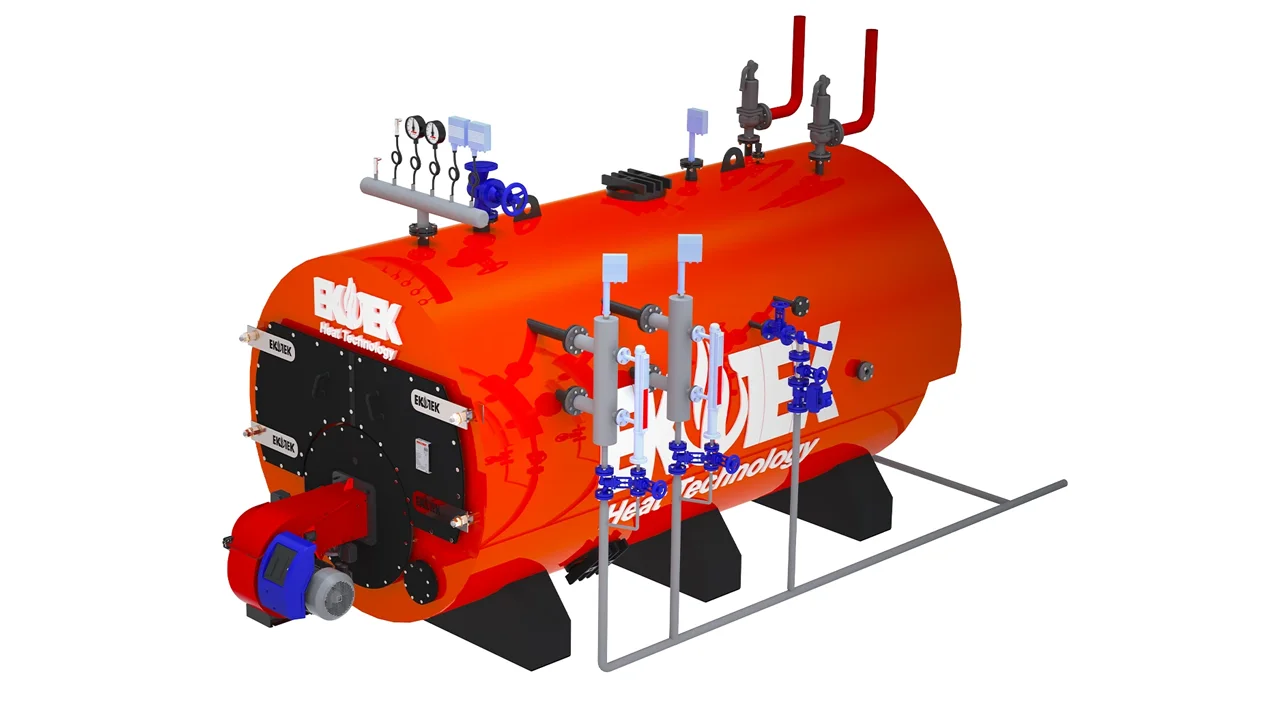

Marine Type Steam Boiler

A marine type steam boiler is a compact, high-efficiency steam generation system designed specifically for the challenging conditions of the maritime industry. Installed on ships and marine vessels, these boilers supply hot water, heating, and process steam needed during long sea voyages. Built to operate seamlessly under vibration, restricted spaces, and fluctuating loads, they provide dependable and continuous energy onboard.

Design and Construction

Marine steam boilers are generally manufactured in vertical or horizontal fire-tube/smoke-tube configurations, making them suitable for vessels with limited installation areas. Their optimized heat transfer surfaces improve fuel efficiency, while robust boiler plates and special connection systems deliver maximum strength under marine operating conditions.