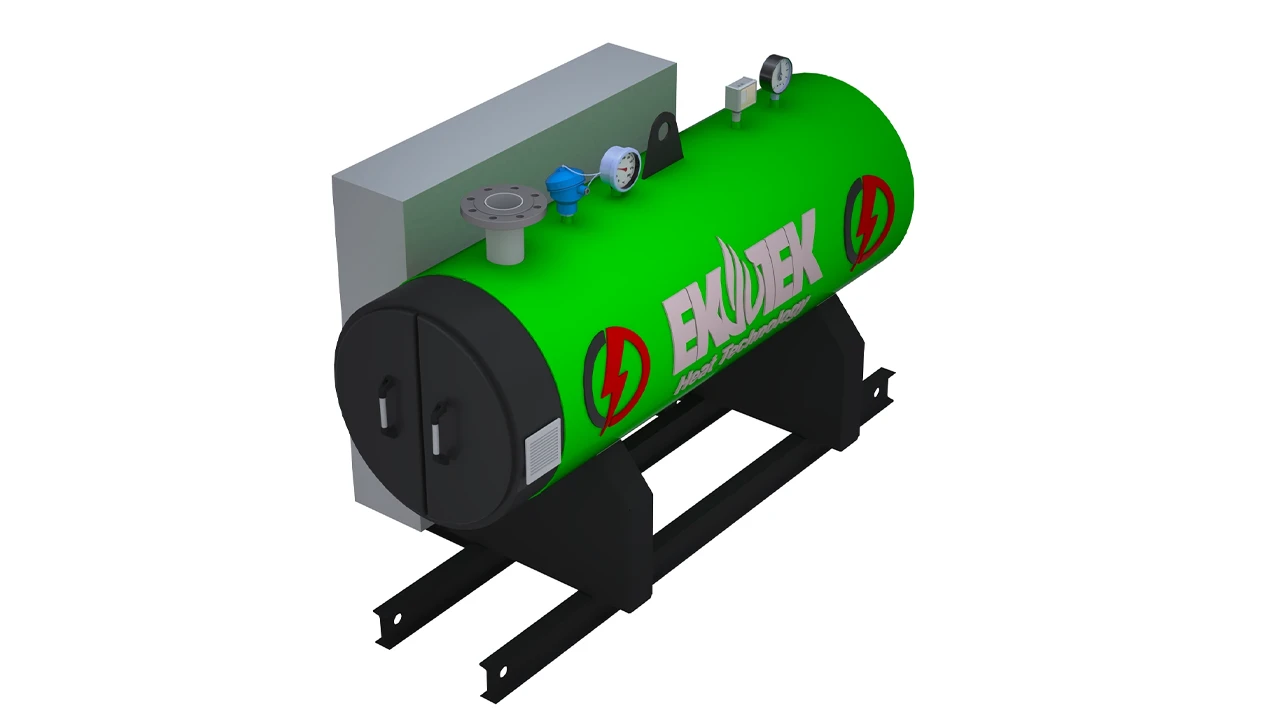

Thermal Oil Boiler - Superheated Oil Boiler

A thermal oil boiler is a type of equipment used in industrial facilities to harness heat energy in applications where pressure cannot be utilized. Unlike steam boilers, it operates at lower pressures while transferring high levels of heat energy effectively.

Thermal oil systems use heat transfer fluids specifically selected based on the thermal load of the application. Upon request, the system can be designed by Ekotek Heat Technologies as a nitrogen-blanketed closed-loop system or as an open-to-atmosphere configuration, tailored to meet your specific operational requirements.