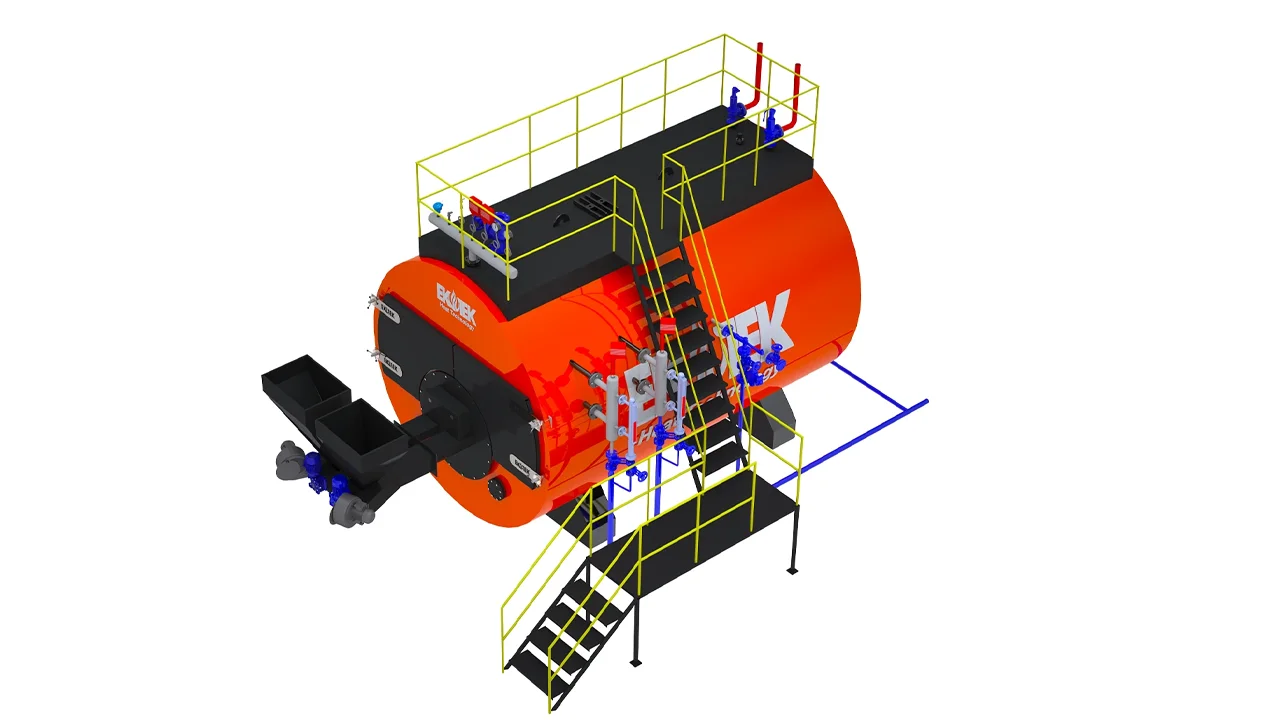

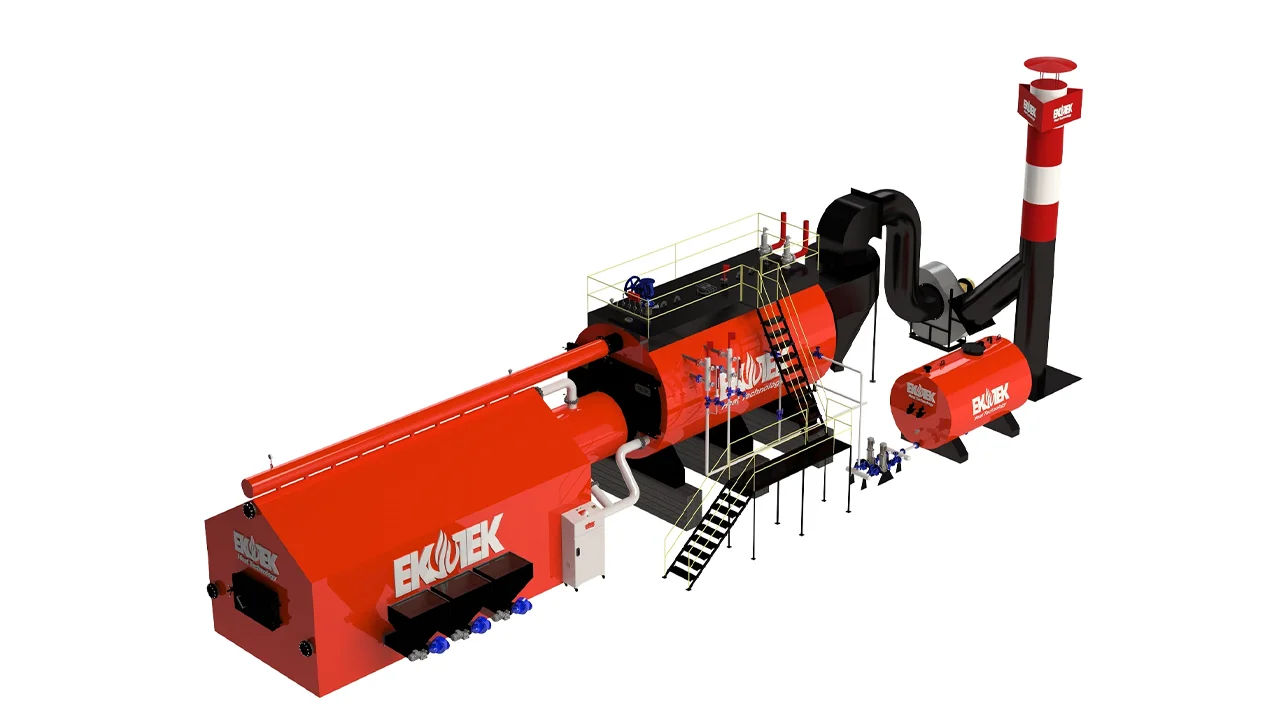

Pellet Boilers

Pellet boilers are machines used to generate heat by burning compressed biological materials known as biomass pellets. These boilers are among the preferred heating systems in terms of both energy efficiency and environmental sustainability. They provide modern heating using a highly efficient, renewable energy source.

Pellet fuel is the only renewable fuel based on biological materials. Therefore, it has started to be preferred a lot in European countries. In modern countries, the consumption of traditional biofuel is increasing with developing awareness.