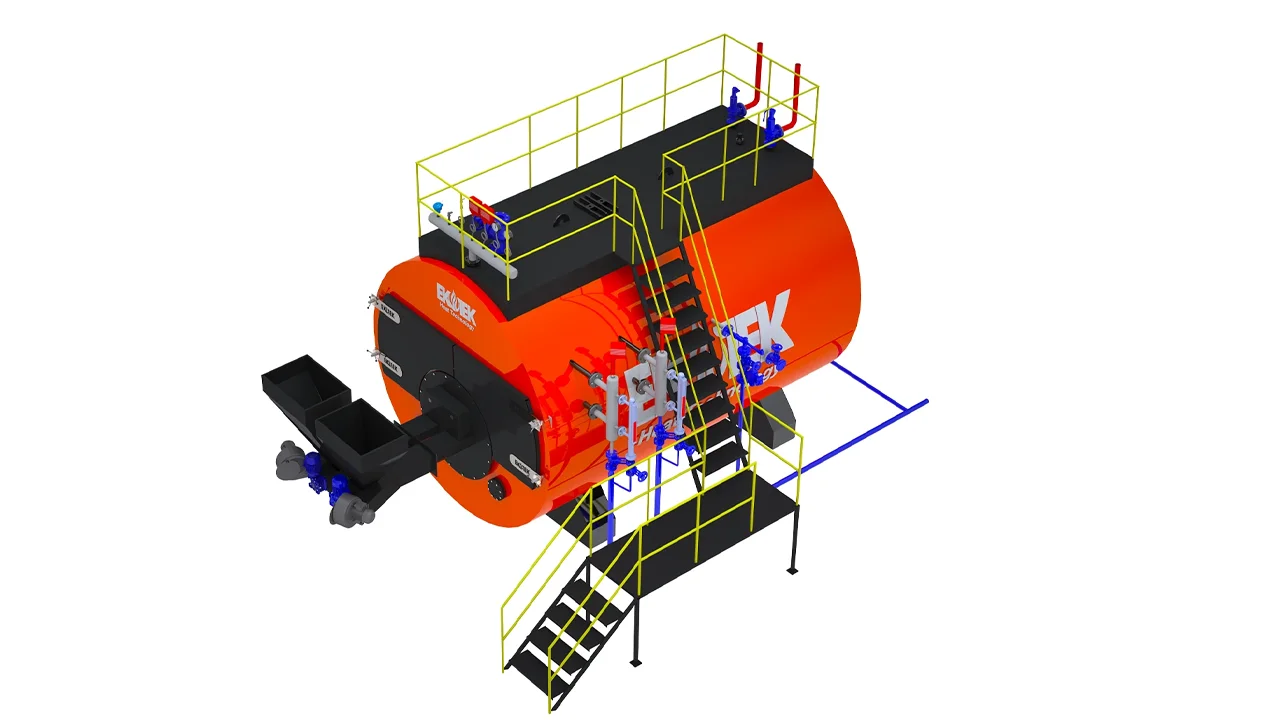

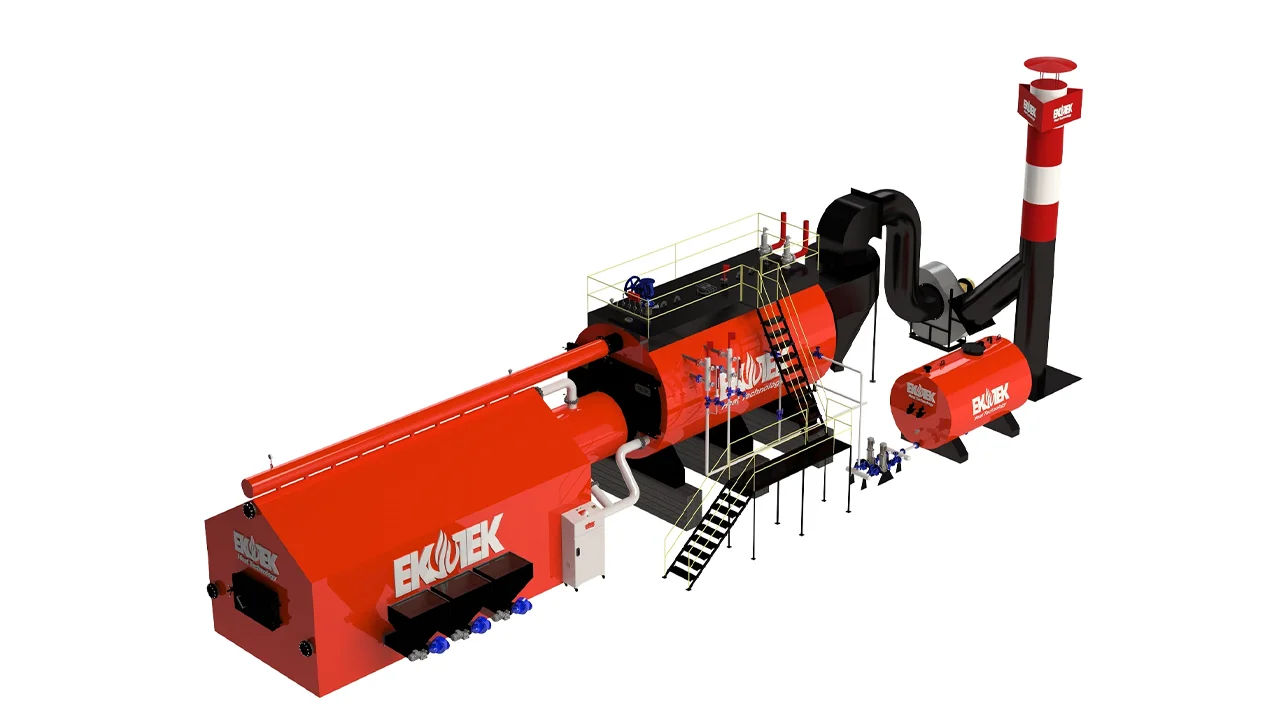

Coal Fired Steam Boiler

Coal fired steam boilers are developed with modern manufacturing techniques and innovative design concepts. As a deep-rooted and widespread energy source, coal remains an indispensable fuel for steam boilers, especially in processes that demand high energy. The coal-fired steam boilers produced by Ekotek Heating Technologies have the capacity to convert the energy of the fuel into steam at the maximum level, offering significant advantages in terms of energy efficiency and environmental sustainability. Thanks to high-efficiency combustion technology, fuel consumption is reduced while emission levels are minimized.