Photo Gallery

Photo Gallery

In the condensate tank system, steam used as the heating fluid transfers its heat energy to the boiler feed water during condensation through the energy transfer method. This process increases the temperature of the boiler feed water. If requested, temperature control automation in the condensate tank can be achieved with a thermostatic valve.

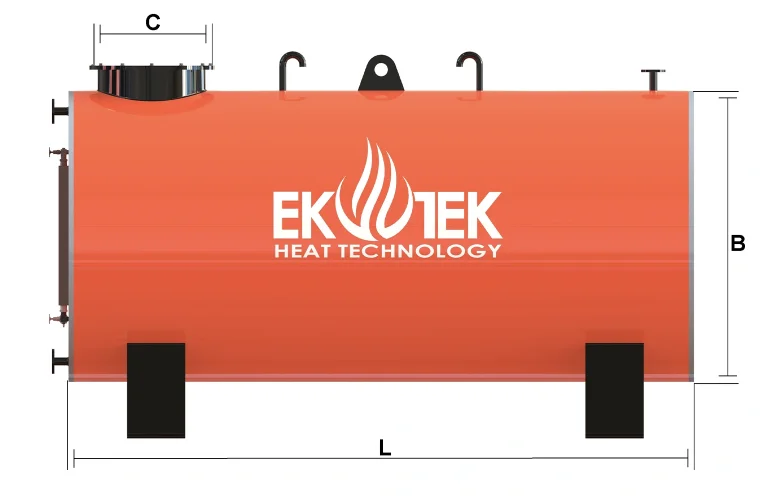

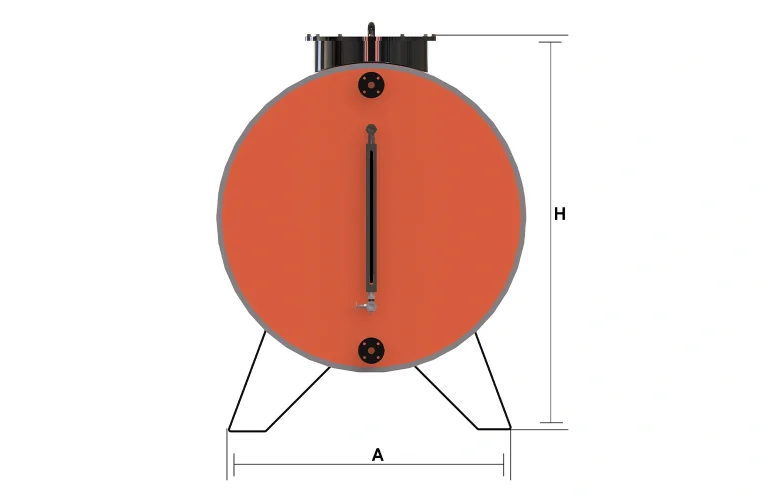

Thermal shocks caused by cold condensate in the boiler are prevented. The condensate tank prevents energy from being released into the atmosphere and ensures heat recovery. It is manufactured in two types: horizontal condensate tank and vertical condensate tank.

The feed water inside the condensate tank is heated either by heating coils or by direct steam entry. At the customer's request, the condensate tank can be insulated with rock wool covered with sheet metal to prevent heat loss from the system to the external environment. Since the feed water does not lose energy in the condensate tank, the amount of energy needed in the boiler is reduced. This results in fuel savings. At the customer's request, it can be delivered as a package (with all fittings included).

Our company EKOTEK is trademark registered and controlled by the ISO 9001:2015 quality management system. Welding operations are carried out by certified welders in accordance with approved WPS and WPQR standards. All products used in production are certified materials. Our products are manufactured using P 265 GH and P 355 GH quality steel sheets according to EN288, EN287-1. Our products are manufactured using boiler tubes made of P235GH and higher quality steel in accordance with TS EN 10217-2 standards. The ideal boiler feed water temperature should be 85°C.